Photovoltaic Power Generation

Photovoltaic Power Generation

Our production facilities utilize a modular layout, with highly coordinated processes across all stages, ensuring high-volume production without compromising product quality. Through scientific scheduling and efficient production management, we can guarantee on-time delivery and meet our customers' urgent needs.

-

01

Visual inspection

Visual inspection

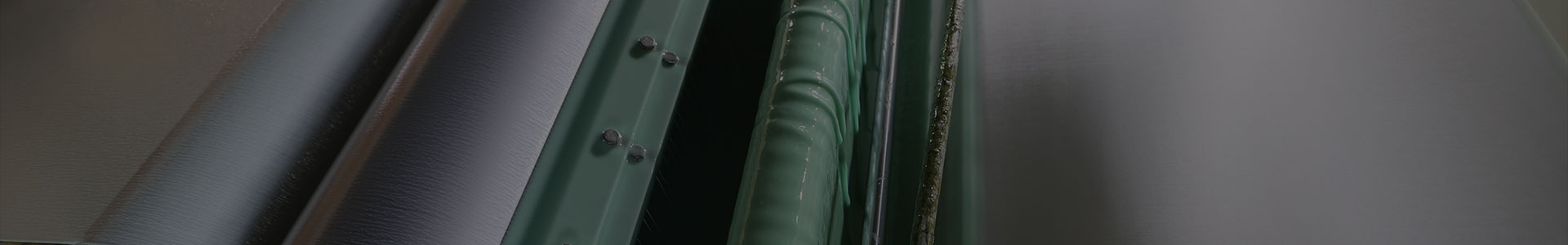

The appearance of epoxy board is an important reflection of quality. We first ensure that each board has a smooth and flawless surface without dents, scratches or other defects. The cross section should be neat and burr-free, avoiding hand thorns and rough sides. We use high-quality equipment for production to ensure the smooth surface of epoxy board and avoid uneven color due to the influence of equipment materials.

Color: The colors of epoxy board usually include aqua, yellow, black and white. We use natural colors and do not add any colorants that may affect the insulation performance. The color of the product may darken over time, but this will not affect its performance.

Surface cleanliness: We conduct strict cleaning inspections on each batch of epoxy board to ensure that there are no impurities, oil or other contaminants to ensure the long-term stability of its appearance and performance.

-

02

Dimensional Accuracy

Dimensional Accuracy

Accuracy Requirements: The dimensions of the epoxy boards will be measured using laser technology and adjusted using CNC equipment to ensure that the dimensions of each board are accurate. Even for custom-sized products, high-precision processing standards are guaranteed to meet customers' stringent dimensional requirements.

-

03

Straightness and Warpage

Straightness and Warpage

The flatness of epoxy boards is one of the important standards for evaluating board quality. We test the warpage of the boards to ensure that they do not deform due to changes in temperature, humidity, or other factors during storage and use.

Bending and Twisting: We check the flatness of each epoxy board to ensure that all four corners and two edges are in the same plane. For thin boards, any improper handling during production may cause warping or fluctuations, affecting the installation and use of the boards.

-

04

Performance Testing

Performance Testing

Strength and Toughness: We ensure the pressure resistance and impact resistance of the boards through bending and stress tests.

Water Resistance and Chemical Corrosion Resistance: We conduct water resistance tests on the boards and test their corrosion resistance under various chemical corrosion environments.

Insulation Performance: As an insulation material, we rigorously test the electrical insulation properties of epoxy boards. Even in harsh environments such as high temperature and humidity, the electrical properties of epoxy boards remain stable.

Yongming Electric is committed to environmental protection and sustainable development. In our production processes, we strictly adhere to environmental regulations, use halogen-free epoxy resins that meet environmental standards, and rigorously treat production waste to minimize our environmental impact.

English

English